Magnetic Detection

Magnetic Detection and Metal Detection Services in Oregon (Eugene & Portland) and Washington State (Everett, Renton, Seattle, & Tacoma)

Identification of ferrous and nonferrous metals: Utilizing Magnetic Locators and Metal Detectors to identify multiple types of utilities and objects, including, well casings, septic tanks, manhole covers, iron pipes, survey markers, valve boxes, steel drums, fuel tanks, etc.

Note: Technical manual providing an overview and product applications: Magnetic Locator Model GA-72CD

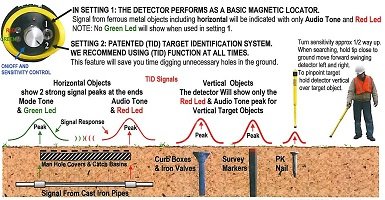

A magnetic detection service will ONLY locate metal objects made of ferrous material. If a magnet sticks to it, a Magnetic Locator will detect it. Understanding how deep in the ground you can detect something depends on its mass. A surveying nail can be found up to about 2’ – 3’ feet deep. An underground storage tank can be found up to about 15’ – 17’ feet deep. Items that are found using magnetic locators are usually cast iron pipes, property corner markers, steel enclosures or hardware, hazmat drums, mag nails, pk nails, manhole covers, marker magnets, septic tank lids, unexploded ordnances, valve boxes, weapons, and well casings.

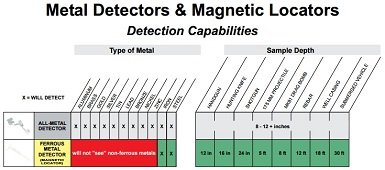

Magnetic detection services will not detect objects such as electrical power cables made of aluminum or copper since these materials are not considered ferrous.

More Information About Magnetic Detection Services

- Ferrous Metal refers to metals with magnetic properties, such as iron and steel. When they come into contact with air and water, they tend to rust over time. Due to their magnetic properties, ferrous metals are easily detectable and are commonly found as contaminants in industrial settings. Some instances of ferrous metal include paperclips, thumbtacks, pins, staples, most screws, nails, washers, welding slag, rust, abrasions caused by metal-to-metal contact, and tools that may have fallen into the conveyor.

- Non-magnetic metals are called non-ferrous metals (copper, aluminum, brass, lead, etc.) They are malleable, lighter in weight than many metals, and resistant to corrosion. Nonferrous metals lack iron, so it is improbable that they will corrode or rust. Nonferrous metals are often used in construction, especially for pipes and gutters. They are recycled at a high rate. Furthermore, this is in part because of their scarcity. These metals are typically more expensive than ferrous metals. Nonferrous metals can be combined with other metals to create alloys. They increase the strength and flexibility of the alloy without the same heavyweight found in ferrous metals. It will take approximately 50% more for a nonferrous metal to be as detectable as a ferrous metal. Manganese is also a nonferrous metal and difficult for most metal detectors to detect. MDI’s digital flat and surround systems are very effective in detecting manganese.

- Stainless Steel is always the most difficult metal to detect due to its poor electrical conductive qualities. By definition, stainless steel has low magnetic permeability. A stainless steel sphere would have to be 50% larger than a ferrous sphere to produce the same signal strength on the metal detector.