Identifying Leaks with Tracer Gas | CNI Locates

Tracer gas leak detection is a highly effective and non-destructive method used to locate and identify leaks in various systems, including pipes, vessels, and other enclosed structures. This process involves introducing a small amount of tracer gas, such as helium or hydrogen/nitrogen, into the system and then using sensitive gas detectors (sniffers) to pinpoint the leak’s location. Further, it can only be performed by a leak detection specialist with experience.

C-N-I Locates’ tracer gas leak detection is often used with other leak detection methods, such as acoustical leak detection, visual inspections, and more, to provide a comprehensive and reliable assessment of the system’s integrity. Lastly, it ensures the safety and reliability of various systems in several residential, industrial, municipal, and commercial applications.

Advantages of Tracer Gas Leak Detection Vs. Acoustical Leak Detection

Tracer gas leak detection and acoustic leak detection are two methods commonly used for leak detection services in various settings such as residential, industrial, commercial, municipal, etc. Here are some advantages of C-N-I Locates tracer gas leak detection compared to acoustical leak detection:

- Detection of Smaller Leaks

Tracer gas leak detection can detect leaks as small as 1×10-6 standard cubic centimeters per second, whereas acoustical leak detection is generally limited to detecting leaks of at least 1×10-4 standard cubic centimeters per second. Our leak detection specialist suggests that it means that tracer gas leak detection is more sensitive and can detect smaller leaks that may not be detectable by acoustical leak detection.

- Precise Location of Leaks

Tracer gas leak detection helps provide the precise location of leaks, as the tracer gas can be introduced at a specific point and tracked as it escapes. This helps identify the source of the leak, making repairs easier and more efficient. Acoustical leak detection, on the other hand, generally relies on the sound of the escaping air, gas, or water, which may not provide as precise a location.

- Non-Destructive Testing

C-N-I Locates’ tracer gas leak detection is a non-destructive testing method. This can be particularly important in situations where the pipe tested is expensive or difficult to replace.

- No Interference from Background Noise

Tracer gas leak detection is not affected by background noise, which can be a problem with acoustical leak detection. In noisy environments, it may be difficult for a leak detection specialist to hear the sound of the escaping air, gas, or water making it more difficult to detect leaks accurately.

Types of Tracer Gas Used for Leak Detection

Two of the most common types of tracer gasses used by leak locating companies for leak detection are helium and a 95% nitrogen/5% hydrogen mix. Read on to know more about them!

- Helium

Helium is a non-toxic, tasteless, odorless, non-flammable, and non-reactive gas that is commonly used as a tracer gas for leak detection. Its low concentration in the atmosphere and its high molecular weight make it an excellent choice for detecting small leaks in various types of equipment, such as refrigeration systems, heat exchangers, and pipelines.

Due to a high demand, helium is typically harder to find and more expensive.

- 95% Nitrogen/5% Hydrogen

Nitrogen gas is non-toxic, odorless, tasteless, and non-flammable. Hydrogen gas is non-toxic, odorless, tasteless, flammable, and explosive. When less than 5.5% of hydrogen gas is mixed with 94.5% or more of nitrogen gas it makes a nonflammable gas that is commonly used as a tracer gas for leak detection because of its low molecular weight and high diffusivity. Its fast diffusion rate makes it an excellent choice for detecting leaks in pipelines, enclosed structures, or other objects.

Nitrogen (95%)/hydrogen (5%) is usually easier to find than helium and less expensive.

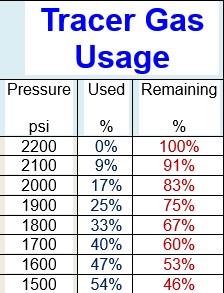

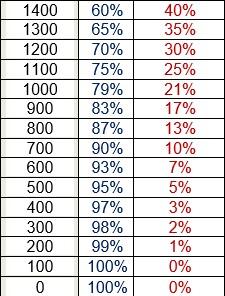

Tracer Gas Tank Usage Rate

Why Is It Important to Use Acoustical Leak Detection and Tracer Gas Leak Detection Together?

Acoustical leak detection and tracer gas leak detection are two techniques commonly used to detect leaks in various residential, commercial, industrial, and municipal settings. While each technique has its own strengths and limitations, our leak detection specialist suggests that using them together can provide a more comprehensive and accurate leak detection solution. Here are some reasons why it is crucial to use acoustical leak detection and tracer gas leak detection together; read on to know!

- Increased Accuracy

When C-N-I Locates technicians use both techniques together it increases the accuracy of leak detection. Acoustical leak detection can detect leaks based on the sound of the escaping air, gas, or water from the pipe. While tracer gas leak detection can sniff for the location of leaking tracer gas to find the leaks source. By combining these techniques, it is possible to obtain more accurate and reliable information about the location and severity of the leak.

- Detection of Different Types of Leaks

Acoustical leak detection and tracer gas leak detection are sensitive to different types of leaks. Acoustical leak detection is most effective for detecting larger leaks, while tracer gas leak detection can detect smaller leaks. By using both techniques together, it is possible to detect a wider range of leaks, including those that might not be detectable by one technique alone.

- Verification of Leak Detection Results

Using both techniques together can help to verify leak detection results. So, if a leak is detected using acoustical leak detection, tracer gas leak detection can be used to verify the leak’s location and vice-versa. We suggest that our technicians try to find the leak acoustically first and then verify the spot with tracer gas leak detection to reduce the amount of tracer gas that is put into the line. When the data correlates between the two leak detection service techniques it provides a more accurate leak detection result.

Limitations of Acoustical Leak Detection and Tracer Gas Leak Detection

While both methods have their advantages, there are also several limitations to each method:

- Limitations of Acoustical Leak Detection

- One of the main limitations of acoustical leak detection is the possibility of noise interference. The method relies on detecting the sound of escaping air, gas, or water which can be challenging in noisy environments. Other sounds, such as machinery or wind, can interfere with the detection of the leak. Additionally, the size and shape of the leak can also affect the sound it produces, making it harder to detect in some cases.

- Other limitations include ability to drill test holes, access to the utility, backflow preventers, frost free hose bibs, landscape matting, obstacles, path of least resistance, pipe depth, pipe length (pipes over 300’ in length may need valves installed), pipe size, plastic pipes (undetectable pipes), property owner not being on site to let us test for the leak inside or to hook up our equipment, size of the leak, slopes, soil the pipe is buried in, surface type, unknown pipes that branch out from the main line, vapor barriers, etc.

- Limitations of Tracer Gas Leak Detection

- The range of the tracer gas used limits tracer gas leak detection. Depending on the type of gas used, detecting leaks in large or outdoor areas may be challenging. Some tracer gasses have a short half-life, which means they dissipate quickly and are unsuitable for long-term monitoring.

- Other limitations include ability to drill test holes, access to the utility, backflow preventers, frost free hose bibs, landscape matting, obstacles, path of least resistance, pipe depth, pipe length (pipes over 300’ in length may need valves installed), pipe size, plastic pipes (undetectable pipes), property owner not being on site to let us test for the leak inside or to hook up our equipment, size of the leak, surface type, unknown pipes that branch out from the main line, vapor barriers, etc.

CNI Locates cannot guarantee the ability to find all leaks due to all the limitations that can occur on a site. If we run into any of the limitations mentioned above, we will notify the client so they can make the executive decision on how they would like to proceed. After the limitations have been addressed, we may need to make a return visit to help identify the location of the leak.

Contact C-N-I Locates for Acoustical & Tracer Gas Leak Detection Services

C-N-I Locates 20+ years of experience makes us one of the best professional leak detection and line locating companies in the industry. Our team of trained and experienced technicians uses state-of-the-art equipment to identify and locate leaks quickly and accurately. At C-N-I Locates, we take safety seriously, and we follow all necessary safety protocols to ensure the safety of our clients and our team. We also take environmental responsibility seriously, and we work hard to minimize our impact of the environment.

Our other services include aerial drone imagery, magnetic detection, metallic line detection, non-metallic line detection, design survey locating, electrical fault detection, ground penetrating radar, plastic water pipe detection, sophisticated reports, structural and concrete scanning, public and private utility locates, sewer crawler inspections, video camera pipe inspections, utility mapping, and more throughout all of Oregon and Washington State. Contact C-N-I Locates at (253)826-1177 or email [email protected] to learn more about how we can help you.